Machine Learning for Manufacturing: Unleashing the Power of Artificial Intelligence

Key Takeaways

- The integration of Artificial Intelligence (AI) and Machine Learning (ML) is revolutionizing the manufacturing industry.

- ML plays a role in predictive maintenance and quality control within manufacturing.

- Implementing AI effectively can give manufacturers an advantage.

- Understanding the applications of AI in manufacturing is essential.

Introduction

Manufacturing is undergoing a transformation as cutting edge technologies like ML and AI are being integrated. This transformation brings about improvements, including increased productivity, enhanced efficiency and new business opportunities. In this article we will explore how machine learning is shaping the future of the manufacturing industry by examining its benefits, applications and impact.

The Unparalleled Benefits of AI and Machine Learning in Manufacturing

The introduction of AI and ML, into manufacturing represents a paradigm shift that offers advantages resulting in improved efficiency and exciting business prospects. Here are some direct benefits;

- Enhanced Efficiency; ML algorithms optimize production processes minimizing losses while maximizing throughput.

- Cost Reduction; Leveraging maintenance powered by ML reduces labor costs through decreased maintenance activities and minimizes inventory wastage.

- Superior Quality Control; By providing insights consistently ML contributes to ongoing product quality improvement.

Improved Management of Supply Chain

Efficiently managing inventory and closely monitoring the flow of production can be achieved by leveraging machine learning.

Manufacturing with a Focus on Customers

A significant advantage of machine learning is the ability to respond quickly to changes in market demand.

Understanding the Reality Behind AI and Machine Learning in Manufacturing;

In the midst of all the excitement surrounding AI and Machine Learning in manufacturing it’s crucial to look beyond the hype and truly grasp the potential these technologies hold. AI is a technology with countless applications and comprehending these contexts is essential for setting realistic business goals when adopting AI.

Identifying Suitable Applications for AI and Machine Learning;

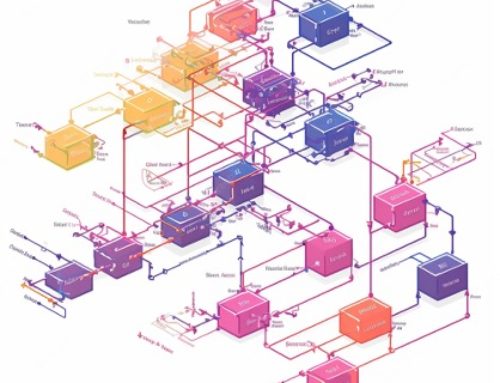

AI performs at its best when applied to solve problems or sets of closely related issues. The same principle applies when incorporating it into manufacturing operations. There are potential applications for AI and Machine Learning in manufacturing each requiring a unique type of artificial intelligence.

Empowering Manufacturers with Next Generation Optimization Using Machine Learning;

Machine learning plays a role in manufacturing through two primary applications; Predictive Quality & Yield as well as Predictive Maintenance.

Predictive Maintenance

One recognized application of machine learning, in manufacturing is predictive maintenance, which employs algorithms to predict component/machine/system failures before they occur.

This method proves to be more effective than maintenance strategies because it prevents unnecessary downtime and reduces costs.

Predicting Quality and Yield

The utilization of AI also known as “Predictive Quality ” uncovers the underlying causes behind the recurring production losses that manufacturers face on a daily basis. It employs multivariate analysis powered by Machine Learning algorithms that are specifically trained to deeply understand each production process.

Differentiating Between Two Main Categories of Machine Learning

When applied to manufacturing Machine Learning can be categorized into two techniques; Supervised and Unsupervised.

Supervised Machine Learning

Supervised Machine Learning is widely used in manufacturing as it aims towards achieving a predefined target. It requires involvement, including data input, data training, algorithm selection, data visualization and more.

Regression and Classification

Regression and Classification are the most commonly employed approaches within Supervised Learning in manufacturing. Regression is utilized when data falls within a range while classification is applied when data can be grouped into distinct categories.

Unsupervised Machine Learning

Unsupervised learning proves beneficial in cases where the outcome’s yet unknown. It encompasses techniques such as clustering which aids in identifying patterns within the data along with Artificial Neural Networks which serve as an effective tool for various applications, in manufacturing.

Preparing Data; Ensuring Accuracy

When it comes to machine learning data is at the core. To achieve results it’s essential to have a clear understanding of the quality and type of data required. Gathering data from sources and clearly defining the question that the machine learning model aims to answer are critical steps.

In Conclusion

The integration of AI and machine learning, in the manufacturing industry is transforming processes and operations leading to efficiency, cost reduction and quality control. However it is vital to grasp the applications of these technologies and their potential benefits in order to effectively leverage them. As we continue to harness the power of machine learning for manufacturing purposes the future of this industry holds promise.

References

Are you interested in AI but don’t know where to start? Want to understand the role of an AI Architect? Check out our page and watch our informative video.